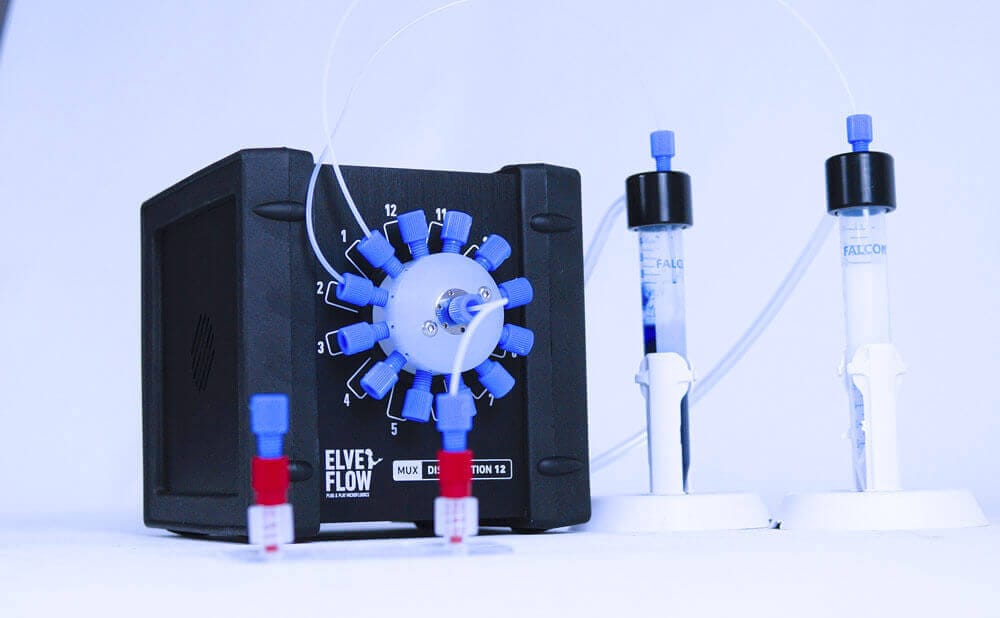

Perfect microfluidic bidirectional rotary selector valve for handling several samples & automating experiments!

SEQUENTIAL MICROFLUIDIC LIQUID INJECTION

⇒Quickly swap your biological media or chemical solutions

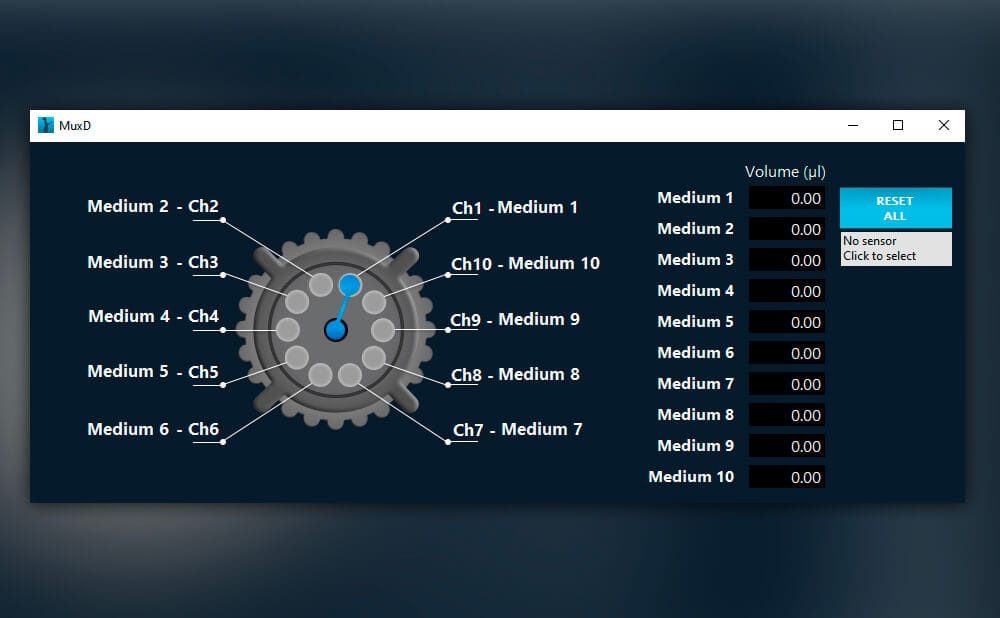

WORKFLOW MICROFLUIDIC AUTOMATION

⇒Save time thanks to sequence programming

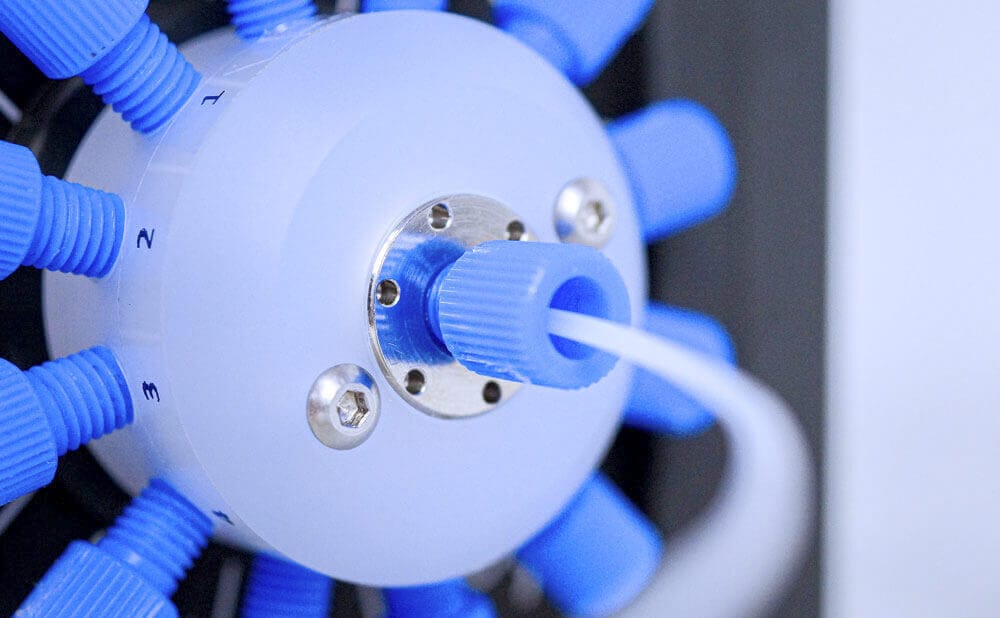

ROTARY SELECTOR VALVE

⇒Switch between up to 12 liquids

PERFUSE SOLUTIONS INTO A MICROFLUIDIC CHIP

⇒Inject 1 sample into 12 outputs or 12 samples into 1 output

Highlights

Perform microfluidic sequential injection with the New 12/1 Rotary Selector Bidirectional Valve. Combined with the OB1 MK3+ pressure controller, it will allow you to automate injection in microfluidic experiments, program perfusion experiments, sequentially supply different reagents and many more applications.

Benefits

Several solutions from one outlet or one feed directed into different outlets.

Use the MUX Distrib to sequentially inject up 12 different solutions into one microfluidic line for sample collections or parallel experiments.

•Low internal volume

•Fast switching time

•Workflow microfluidic automation

•Smooth switches: no disruption of the flow

•Easy setup and operation (plug and play software + standard fluidic connection)

Key advantages

- Valve flexibility: 13 ports

- Easy setup: standard ¼-28 fluidic fittings

- Possibility to chose the sense of rotation

- High chemical compatibility

- Lowest internal volume: 3.5 µL

- No dead volume

- Switching time (average): 156 ms

- Wetted materials: PCTFE, PTFE

Applications

The MUX Distrib’ 12/1 can be used in various fields of application and for any experiment that requires successive injection of fluids: from organic synthesis, flow chemistry, drug screening, biochemical and electrochemical sensor calibration, calibration (bench testing), sensors test rig, toxicity test, Seq-Fish experiment…

Application notes

- How to control the flow while flow line changing with a Mux Distributor ?

- How to perform fast drug or medium switch?

- How to perform controlled drug switches with an Elveflow® MUX?

- How to perform an ultrafast microfluidic medium switch with an Elveflow® pressure & flow control instrument (OB1)

- How to perform the injection of a controlled volume of sample?

For more biology-related content, please refer to the cell perfusion application pack.

Publications

Adaptable pulsatile flow generated from stem cell-derived cardiomyocytes using quantitative imaging-based signal transduction

T. Qian et al., Lab on a Chip, 2020, 20, 3744-3756, DOI: 10.1039/D0LC00546K

Microfluidic platform for 3D cell culture with live imaging and clone retrieval

C. Mulas et al., Lab on a chip, 2020, 20, 2580-2591, DOI: 10.1039/D0LC00165A

Microfluidic Control of Nucleation and Growth of CaCO3

D. K. Dysthe et al. Cryst. Growth Des. 2018, 18, 8, 4528–4535

Specifications

| NEW 12/1 valve | ||

| Category | Parameter | Value |

| Performances | Port to port switching time (ms) | 156 ms |

| Max recommended pressure | 7 bar | |

| Internal diameter | 0.5 mm | |

| Internal volume(1) | 3.5 µL | |

| Carryover volume(2) | 1.7 µL | |

| Dead volume (3) | None | |

| Wetted materials | PCTFE, PTFE | |

| Number or ports | 13 | |

| Number of positions | 12 | |

| Operating temperature | 5-40°C | |

| Operating Humidity | 20-70% noncondensing |

- Volume inside the system from entrance to exit

- Volume of liquid that will be mixed with the next liquid. It is not stuck, but will be swept next time a liquid passes.

- Volume that is stuck in the system (dead end), which is not clearly swept and relies on diffusion to clear out